https://www.sciencedirect.com/science/article/pii/S240588662500048X?via%3Dihub

AM Technologies by Brinter is proud to announce that our advanced 3D bioprinting equipment and modular tool head played a pivotal role in groundbreaking research on dual-crosslinkable gallol bioinks, recently published in Biofabrication.

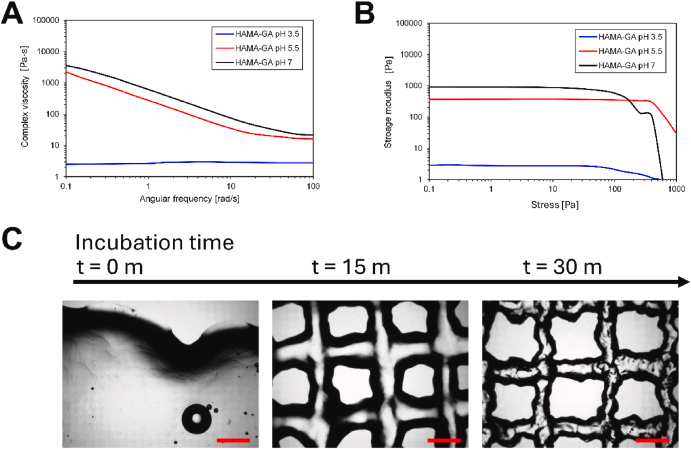

Researchers from distinguished European institutions leveraged the Brinter AM extrusion-based bioprinter and tool head to fabricate next-generation hydrogel scaffolds. Their innovative approach combined pH-controlled oxidative crosslinking with versatile photocrosslinking—creating bioinks that are not only shear-thinning and highly printable, but also demonstrate enhanced mechanical stability and wet tissue adhesion.

Enabling Scientific Breakthroughs

The Brinter AM bioprinter was integral in:

- Achieving precise, reproducible extrusion of gallol-modified hyaluronic acid methacrylate (HAMA-GA) bioinks at optimal pH and temperature conditions.

- Seamlessly integrating multi-step dual crosslinking—allowing researchers to fine-tune bioink properties with both temporal oxidation and rapid UV-induced network stabilization.

- Supporting sophisticated multi-layer grid printing and tailored construct geometries while minimizing common print failures such as nozzle clogging and filament spreading.

These advances demonstrate the flexibility and reliability of Brinter AM modular hardware in addressing the evolving demands of bioprinting research for tissue engineering, wound care, and organ-on-chip models.

Amplifying Impact in Regenerative Medicine

AM Technologies by Brinter continues to empower leading innovators worldwide with robust modular 3D bioprinting solutions. The successful application of our technology in this high-profile publication exemplifies our shared mission to accelerate healthcare breakthroughs through precision biomanufacturing.

Learn more about our bioprinting tools or contact us to explore partnership opportunities in applied biofabrication.

Hatai Jongprasitkul, Sanna Turunen, David A. Fulton, Minna Kellomäki, Vijay Singh Parihar,

Dual-crosslinkable gallol bioinks via pH-controlled oxidation and photocrosslinking with enhanced shear thinning and viscoelastic behavior,

Bioprinting,

Volume 50,

2025,

e00432,

ISSN 2405-8866,

https://doi.org/10.1016/j.bprint.2025.e00432.

(https://www.sciencedirect.com/science/article/pii/S240588662500048X)

Abstract: Our research work proposes a dual crosslinking approach to address the limitations of the gallol-mediated auto-oxidation approach in bioprinting, where rapid oxidative crosslinking can cause premature gelation, leading to clogging or printing failure. We enabled a gallol hydrogel ink to be printable via extrusion-based 3D bioprinting by utilizing its temporal shear-thinning properties. By raising the pH level, interactions between gallol-modified hyaluronic acid methacrylate (HAMA-GA) can be triggered to form a weak hydrogel. This feature provides injectability and extrudability for the hydrogels. Subsequent photocrosslinking results in indefinite oxidative crosslinking. The oxidative coupling in HAMA-GA was partially inhibited by UV light during the photocrosslinking step. As a result, the printed hydrogel formed a dual-crosslinked network containing both oxidative and photo-induced bonds, which contributed to enhanced structural stability over time. Our proposed approach addresses the challenges of gallol-mediated oxidation, including overgelation that hinders extrusion in 3D bioprinting, offering a promising solution for improved printability and shape fidelity. HAMA-GA ink was bioprintable at pH 5.5 using an extrusion-based 3D printer, showing cytocompatibility (∼95 % viability). This strategy is valuable for designing hydrogel inks with tunable properties for 3D bioprinting while maintaining tissue adhesive properties of gallol moieties.

Keywords: Bioprinting; Injectable hydrogels; Gallol-based biomaterials; Hyaluronic acid; Photocrosslinking; Dual crosslinking

Join Us on the Journey

We invite you to follow Brinter AM Technologies as we work together to revolutionize healthcare through additive manufacturing. Stay connected for updates on our progress, breakthrough research, and opportunities to collaborate in transforming life sciences.

Together, let’s build the future of healthcare—one innovative layer at a time!

For further updates, follow our page on LinkedIn